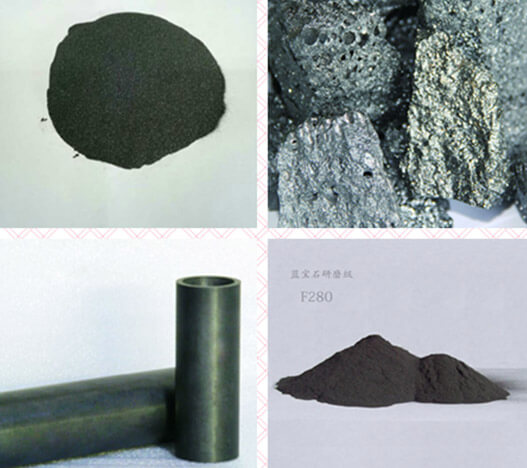

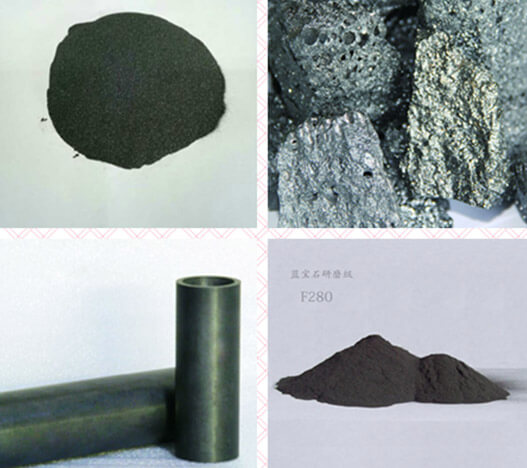

B4C is produced by high temperature smelting boric acid and carbon material in electric furnaces. It theoretic density is 2.52g/cm3, the melting point is 2450℃ ,and the micro hardness is 4950kgf/mm.

2. Its hardness is just lower than diamond and cubic B4C. Because of high temperature resistance, acid and alkali resistance, high strength, good chemical stability, and low specific weight, It is widely used in many new materials fields.

B4C is produced by high temperature smelting boric acid and carbon material in electric furnaces. It theoretic density is 2.52g/cm3, the melting point is 2450℃ ,and the micro hardness is 4950kgf/mm2. Its hardness is just lower than diamond and cubic B4C. Because of high temperature resistance, acid and alkali resistance, high strength, good chemical stability, and low specific weight, It is widely used in many new materials fields.

| Type | Size | Basic Grain (um) | B % | C % | Fe2O3 % | B4C% |

| Typical Sand | F40 | 425 | 76-80 | 17-21.5 | 0.2-0.4 | 95-99 |

| F46 | 355 | |||||

| F54 | 300 | |||||

| F60 | 250 | |||||

| F70 | 212 | |||||

| F80 | 180 | |||||

| F90 | 150 | |||||

| F100 | 125 | |||||

| F120 | 106 | |||||

| F150 | 75 | |||||

| F180 | 75-63 | |||||

| F220 | 63-53 | |||||

| Typical Fines | F230 | D50=53 | 75-79 | 0.3-0.5 | 95-97 | |

| F240 | D50=44.5 | |||||

| F280 | D50=36.5 | |||||

| F320 | D50=29.5 | |||||

| F360 | D50=22.8 | 0.3-0.6 | ||||

| F400 | D50=17.3 | |||||

| F500 | D50=12.8 | 0.4-0.8 | ||||

| F600 | D50=9.3 | 74-79 | 0.3-0.7 | 93-97 | ||

| F800 | D50=6.5 | 0.4-0.9 | ||||

| F1000 | D50=4.5 | |||||

| F1200 | D50=3.0 | 0.5-0.9 | ||||

| F1500 | D50=2.0 | |||||

| Scope Fines | 100#-0 | 150max | 75-80 | 17-21 | 0.3 max | |

| 200#-0 | 90max | |||||

| 325#-0 | 45max | |||||

| 60#-150# | 250-75 | |||||

| 25um-0 | 25max | |||||

| 10um-0 | 10max | |||||

| 3um-0 | 3max |

1. High temperature resistance

2. Strong acid-alkali resistance

3. High wearing resistance

4. Excellent chemical stability

5. Low specific weight

6. The oxidation resistance

Application Area:

1. As refractory material

(1) Low carbon magnesia bricks

(2) Ladle castable

(3) Tap hole(nozzle)

(4) Sliding plate and stopper bar

2. Used in abrasives

(1) Sapphire crystal slice lapping and polishing

(2) Water cutting abrasives

(3) High-grade wear-resistant electrode

(4) Used for jewelry grinding, polishing, drilling and polishing

3. For engineering ceramic materials

(1) Sandblasting machine nozzle

(2) High pressure water cutting machine nozzle

(3) Ring seal

(4) Mould for ceramics

4. Used in bulletproof material and nuclear industry

(1) Military bullet-proof products

(2) Produce the nozzles of gun and artillery

(3) Radiation resistant

(4) Nuclear reactor controlling bars, adjust bars, safety bars, screen bars .